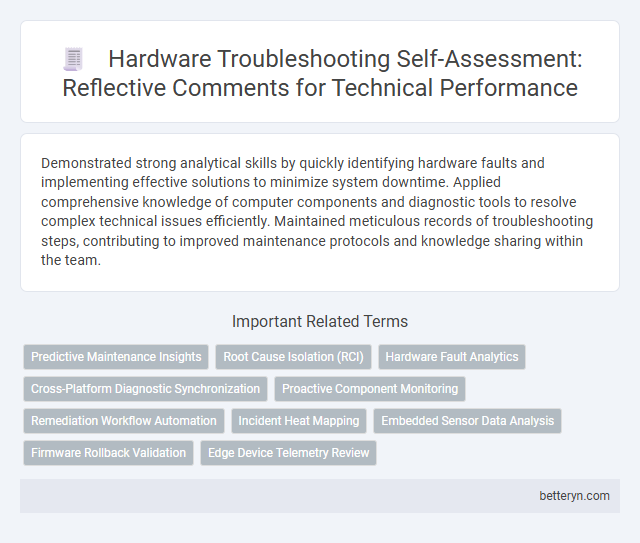

Demonstrated strong analytical skills by quickly identifying hardware faults and implementing effective solutions to minimize system downtime. Applied comprehensive knowledge of computer components and diagnostic tools to resolve complex technical issues efficiently. Maintained meticulous records of troubleshooting steps, contributing to improved maintenance protocols and knowledge sharing within the team.

self evaluation comments for hardware troubleshooting

Accurately identified and diagnosed hardware issues using systematic troubleshooting techniques.

Accurately identifying and diagnosing hardware issues using systematic troubleshooting techniques enhances problem-solving efficiency and reduces downtime. This skill ensures precise detection of faults, enabling quicker repairs and minimizing operational disruptions. Improved troubleshooting capabilities contribute to overall system reliability and demonstrate technical proficiency essential for professional growth.- How effectively did I apply systematic troubleshooting techniques to diagnose hardware issues?

- Did I accurately identify the root cause of each hardware problem encountered?

- How well did I document the troubleshooting process and findings for future reference?

- Were there any instances where initial diagnostics were incorrect, and how did I adjust my approach?

- How consistently did I use diagnostic tools and resources to ensure accurate hardware issue resolution?

Effectively utilized diagnostic tools to isolate and confirm hardware faults.

Mastering diagnostic tools enabled precise identification and confirmation of hardware faults, significantly reducing downtime and repair costs. This skill enhanced troubleshooting efficiency and contributed to maintaining optimal system performance. Developing expertise in diagnostics is essential for accelerating problem resolution and supporting continuous professional growth in technology maintenance.- How accurately did I identify hardware faults using diagnostic tools?

- Did I select the most appropriate diagnostic tool for each hardware issue?

- How efficiently did I use diagnostic tools to minimize troubleshooting time?

- Was I thorough in confirming hardware faults before proceeding with repairs?

- How well did I document diagnostic results to support repair decisions?

Demonstrated strong attention to detail while inspecting and handling hardware components.

Demonstrating strong attention to detail while inspecting and handling hardware components ensures the identification of potential faults and quality issues early in the process. This meticulous approach reduces the risk of equipment failure and enhances overall system reliability. Consistent focus on detail fosters improved technical skills and a proactive mindset essential for continuous professional development.- How consistently do I identify and address small defects or issues during hardware inspections?

- In what ways have I improved the accuracy of my handling procedures for hardware components?

- How effectively do I document and communicate findings related to hardware quality?

- What steps do I take to ensure components are free from damage before installation or shipment?

- How do I prioritize thoroughness without compromising efficiency in my inspection process?

Maintained thorough documentation for all troubleshooting steps and outcomes.

Maintained thorough documentation for all troubleshooting steps and outcomes to ensure clear communication and efficient problem resolution. This practice enhances knowledge sharing within the team and supports continuous improvement by providing a reliable reference for future issues. Consistent documentation contributes to faster troubleshooting, reduces repeat errors, and promotes overall professional growth.- How consistently did I document each troubleshooting step during issue resolution?

- Were the documented troubleshooting steps detailed enough to be easily followed by others?

- Did I include all relevant outcomes and observations in the documentation?

- How effectively did my documentation contribute to faster problem resolution in future incidents?

- Did I update the documentation promptly and accurately after every troubleshooting session?

Collaborated efficiently with team members to resolve complex hardware problems.

Collaborating efficiently with team members to resolve complex hardware problems significantly enhances problem-solving speed and quality. This teamwork fosters knowledge sharing and innovation, leading to more robust and reliable hardware solutions. Your active participation in collaborative efforts drives both personal growth and overall project success.- How effectively did I communicate with team members during hardware problem-solving?

- Did I actively listen and incorporate feedback from colleagues when addressing hardware issues?

- How well did I contribute my technical skills to the team's hardware troubleshooting efforts?

- Was I proactive in offering solutions and supporting team members in resolving complex hardware problems?

- How did my collaboration impact the overall success and timeliness of hardware issue resolution?

Proactively applied preventative measures to minimize future hardware failures.

Proactively applying preventative measures significantly reduces the risk of hardware failures, ensuring system reliability and operational continuity. This approach not only extends the lifespan of hardware components but also minimizes downtime and maintenance costs. Emphasizing proactive maintenance enhances overall efficiency and supports sustained growth in technological infrastructure.- How effectively have I identified potential hardware failure risks before they occur?

- What specific preventative measures have I implemented to reduce hardware failures?

- How consistently do I monitor hardware health to preemptively address issues?

- In what ways have my proactive actions improved overall system reliability?

- How have I documented and shared preventative strategies to benefit the team?

Responded promptly to hardware incidents, reducing equipment downtime.

Responding promptly to hardware incidents minimizes equipment downtime, ensuring continuous workflow and productivity. Quick issue resolution prevents extended disruptions and costly repairs, supporting overall operational efficiency. Your proactive approach contributes significantly to maintaining system reliability and fostering a smooth work environment.- How quickly did I respond to hardware incidents to minimize downtime?

- What steps did I take to identify and resolve hardware issues efficiently?

- How effectively did I communicate hardware problems and solutions to the team?

- Did I proactively monitor hardware to prevent potential incidents?

- What improvements can I make to further reduce hardware-related downtime?

Continuously updated my knowledge on emerging hardware technologies and troubleshooting best practices.

Consistently updating my knowledge on emerging hardware technologies ensures I stay proficient with the latest tools and methodologies. This commitment enhances my troubleshooting skills, enabling faster and more accurate problem resolution. Such continuous learning drives my professional growth and increases my value as a technical expert.- How effectively have I incorporated new hardware technologies into my daily work processes?

- What specific steps have I taken to stay informed about the latest hardware trends and troubleshooting techniques?

- How have I applied newly acquired knowledge to resolve complex hardware issues?

- In what ways have I shared updated hardware knowledge with my team to improve overall performance?

- How do I measure my progress and effectiveness in mastering emerging hardware technologies?

Safely adhered to proper ESD and handling protocols during repairs and replacements.

Safely adhering to proper ESD and handling protocols during repairs and replacements minimizes the risk of damaging sensitive electronic components, ensuring product reliability and longevity. This careful attention to electrostatic discharge control demonstrates your commitment to maintaining high-quality standards and protecting valuable equipment. Consistently following these safety measures supports professional growth by reinforcing discipline and technical competence.- Did I consistently use ESD-safe tools and equipment during all repair tasks?

- How effectively did I ground myself before handling sensitive electronic components?

- Did I inspect all materials for ESD compliance prior to use in repairs?

- Was I able to identify and correct any ESD risks during the repair process?

- How well did I document adherence to ESD protocols in each repair or replacement task?

Important Terms

Predictive Maintenance Insights

Analyzed hardware performance data to identify early signs of failure, enabling targeted predictive maintenance and reducing unexpected downtime. Leveraged predictive maintenance insights to optimize troubleshooting processes, enhancing overall system reliability and operational efficiency.

Root Cause Isolation (RCI)

Demonstrated strong expertise in Root Cause Isolation (RCI) by systematically analyzing hardware faults and identifying underlying issues with precision. Utilized advanced diagnostic tools and logical methodologies to efficiently pinpoint and resolve complex hardware failures, minimizing downtime and improving system reliability.

Hardware Fault Analytics

Demonstrates proficiency in hardware fault analytics by accurately diagnosing complex component failures and identifying root causes through systematic data analysis. Consistently improves troubleshooting efficiency by leveraging predictive maintenance techniques and detailed fault pattern recognition.

Cross-Platform Diagnostic Synchronization

Demonstrates expertise in cross-platform diagnostic synchronization by efficiently aligning hardware troubleshooting protocols across diverse operating systems to minimize downtime. Consistently applies advanced diagnostic tools and methodologies to ensure seamless hardware issue identification and resolution in multi-environment settings.

Proactive Component Monitoring

Consistently implement proactive component monitoring to identify potential hardware failures before they impact system performance, enhancing overall reliability and reducing downtime. Utilize diagnostic tools and real-time data analysis to detect anomalies early, enabling timely interventions and preventative maintenance.

Remediation Workflow Automation

Implemented automated remediation workflows that significantly reduced hardware downtime by enabling real-time issue detection and resolution. Optimized troubleshooting processes through integration of diagnostic tools with automated response mechanisms, enhancing system reliability and efficiency.

Incident Heat Mapping

Utilized Incident Heat Mapping to identify high-frequency hardware failure points, enabling targeted troubleshooting and reducing downtime significantly. Leveraged data insights to prioritize maintenance efforts and improve overall system reliability.

Embedded Sensor Data Analysis

Demonstrated proficiency in embedded sensor data analysis by accurately identifying hardware anomalies and root causes, leading to efficient troubleshooting and reduced system downtime. Consistently applied advanced diagnostic techniques and optimized firmware parameters to enhance sensor reliability and performance in embedded systems.

Firmware Rollback Validation

Performed comprehensive firmware rollback validation to ensure system stability and compatibility across multiple hardware configurations, identifying and resolving potential conflicts that could disrupt normal operations. Utilized diagnostic tools to verify successful reversion to previous firmware versions, minimizing downtime and enhancing troubleshooting accuracy.

betteryn.com

betteryn.com